Rigid foam cutting for prototypes, individual pieces or small series

Favourable professional cutting for rigid foam sheets: standard cuts, objects, furniture, letters & logos. The offer is aimed at industry, trade and private individuals.

Saxoboard is also setting new standards in the field of polystyrene foam customisation. Thanks to many years of experience in the processing and manufacture of products made of XPS, EPS and PP rigid foams, also known under the trade names Styrodur and Styrofoam as well as polypropylene, we can offer you the highest level of quality and expertise.

- Our range of products in the rigid foam sector includes the production of

- Rigid foam boards offer the following applications

- Our machinery

- Customised solutions made of rigid foam

- All rigid foam blanks are available in the following maximum sizes

- Our services and benefits in the field of rigid foam boards

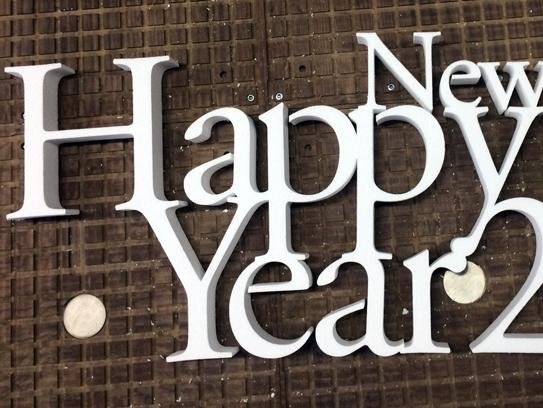

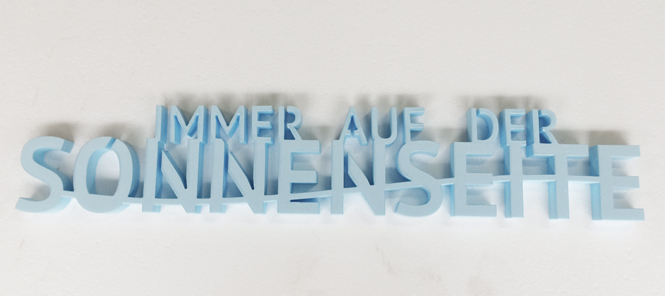

Cutting of panels, furniture, objects, logos and lettering.

Our range of services in the area of rigid foam includes the production of

- POS objects

- furniture

- spheres

- Letters, logos and numbers

- Trade fair objects

- 3D free forms

- 3D advertising objects

- 3D rotational moulds

- Packaging and technical blanks

Our strength lies in the fast, customised and, above all, high-quality production of your desired product from EPS, XPS or PP rigid foam. You can rely on the millimetre-precise cutting of the respective rigid foams so that you always receive the size, thickness and shape you require. The production of oversized sizes is no problem for us.

Rigid foam sheets can be used in the following ways

- for insulation: inside and outside

- as a material for packaging

- as protection against vibrations

- as a material for modelling

- and other possible applications

We achieve this high production quality thanks to our CNC hot wire cutting machines and a large selection of corresponding base materials. With the help of our core technologies of milling and thermal cutting, we can produce cost-effectively without tooling and set-up costs. We are also experts in the field of "foamed moulded parts" and "bonding technology". Thanks to our in-house coating and painting workshop, we are always able to respond flexibly and quickly to your requirements and wishes.

Our machinery

- 3 axis EPS milling machines

- 4 axis CNC contour cutting machines

- 3 axis plate milling machine

- Multi-wire cutting machine

- Coating shop, paint shop and mould making

Customised solutions made from rigid foam

We can offer you individual, customised solutions for your prototypes, small series or unique items. In addition to simple polystyrene cuttings, such as standard sheet material, our strength lies in the cutting of milled, contoured and moulded parts as well as sophisticated packaging systems. This means that, in addition to high-quality standard products, we can also offer you customised solutions tailored to your problem. In addition, it is always possible to supply individual items.

All rigid foam blanks are available in the following maximum sizes

- 2500 mm length

- 2500 mm width

- 1000 mm thickness

We are personally available to fulfil our customers' wishes. We are happy to help you realise your projects with our high-quality rigid foam cuttings, be it the creation of prototypes, one-offs or entire small series.

Our services and advantages in the field of rigid foam sheets

- Fast and flexible response to your needs

- Delivery of customised quality products

- fine-grained, high-quality EPS, XPS and EPP material

- Use of B1-approved materials with fire protection certificate

- single piece delivery possible + optional painting and coating

- Many sizes and thicknesses available

- Cost-effective solution for demanding tasks

- Personal contact person