- Shower tray configurator

- Showers

- Baths & Wellness

- Insulation & filling

-

Tiles

- Sealing

-

Tile profiles

- Tile levelling systems

- Rails & gradient wedges

- Levelling compounds & screeds

- Electric underfloor heating

- Shower and corner shelves

- Wall niches & wall elements

- Tile adhesive & natural stone adhesive

- Planters made of solid surface material

- Tileable washbasins

- Matching accessories

- Building boards

- Guide & Service

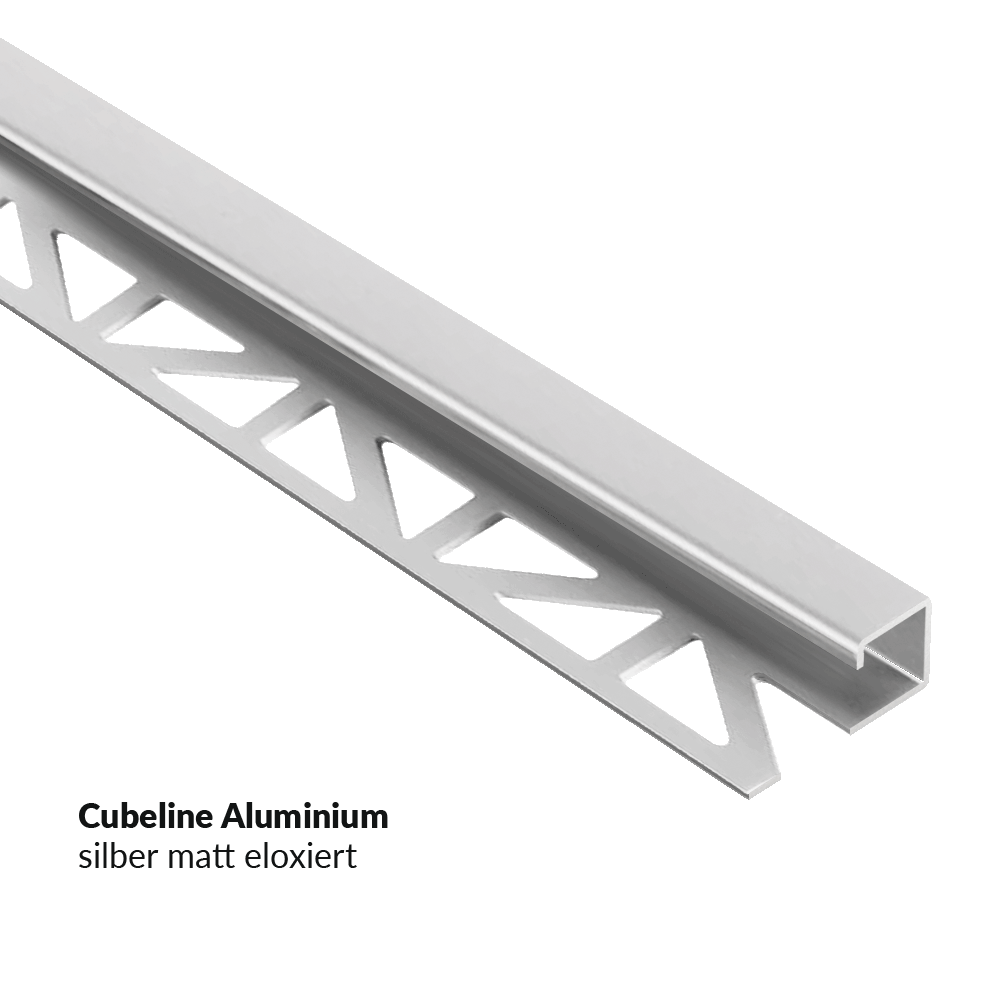

Tile profiles

The right profile for every installation situation: tile profiles (also known as tile rails or end profiles) add value to any tiled area. They not only provide a visual finish, but also protect the tile edges from damage.

Tile rails are versatile

The tile rails can be used in various areas. For example, the profile can be used as a transition between different types of covering(transition profile). Finishing plinths and corners is also no problem with the rails(finishing profile). The profiles can be used not only on floors but also on walls.

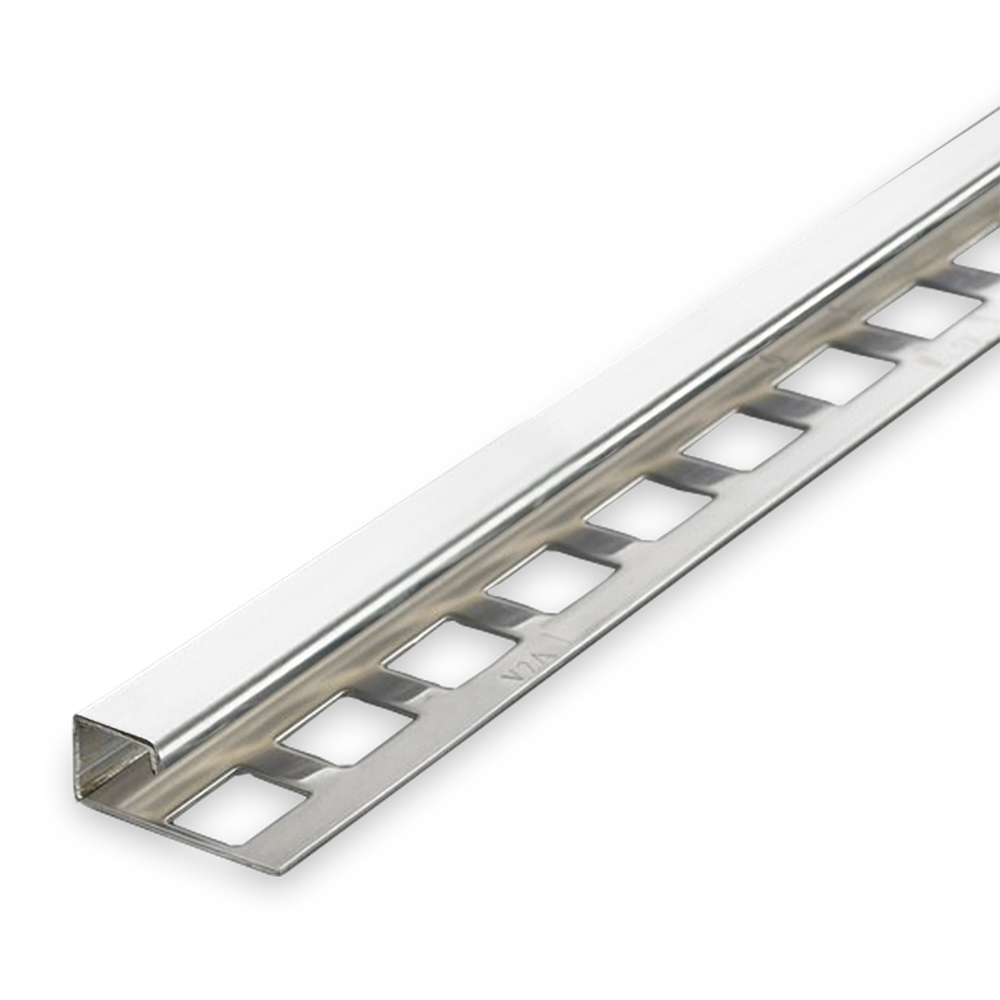

Flexible and resilient material

All tile profiles are made of V2A stainless steel and are therefore also suitable for heavy loads. The profiles can also be cut to your desired size and are available for various tile thicknesses.

- Profiles made of V2A stainless steel

- Can be flexibly cut to size

Easy installation in 3 steps

Installing a tile rail is easy and requires no special knowledge. The tile profile is simply inserted with the fixing leg into the fresh adhesive bed (tile adhesive, tile mortar). The rail is then aligned. In the next step, the tile is pressed into the adhesive bed. Care must be taken to ensure that the top edge of the tile is flush with the top edge of the profile. It is also important to leave a 1 to 1.5 mm wide joint between the tile rail and the tile.

- Cut the tile profile to size if required

- Insert into the adhesive bed and align

- Press in firmly, ensure a flush finish and allow for the joint